At minimum fluidization pressure drop across bed is balanced by effective weight of the particle. Reactor Sizing Reactor Sizing Given r A as a function of conversion -r A fX one can size any type of reactor.

Catalytic Packed Bed Reactor Youtube

In most cases the pressure drop in the reactor is relatively small so that a mean value for the total pressure is used in the calculations.

. 1 Calculate Catalyst wight -W using mole balance equation dxdw -rAFAo 2 Calculate Reactor volume or Bed Volume VR with formulaW VR 1. For instance process parameters eg gas velocity 84 as well as reactor design 85 eg packed bed width and length volume fraction 86 can be optimized systematically to ensure. 62 are the simplest type pf reactor to design and.

Part of the reactor bed Figure4 Packed bed Reactors Kinds of Phases Present Usage Advantages Disadvantages 1. Viscosity μ and density ρ the operating parameter. 3 Behavior of the expanded bed.

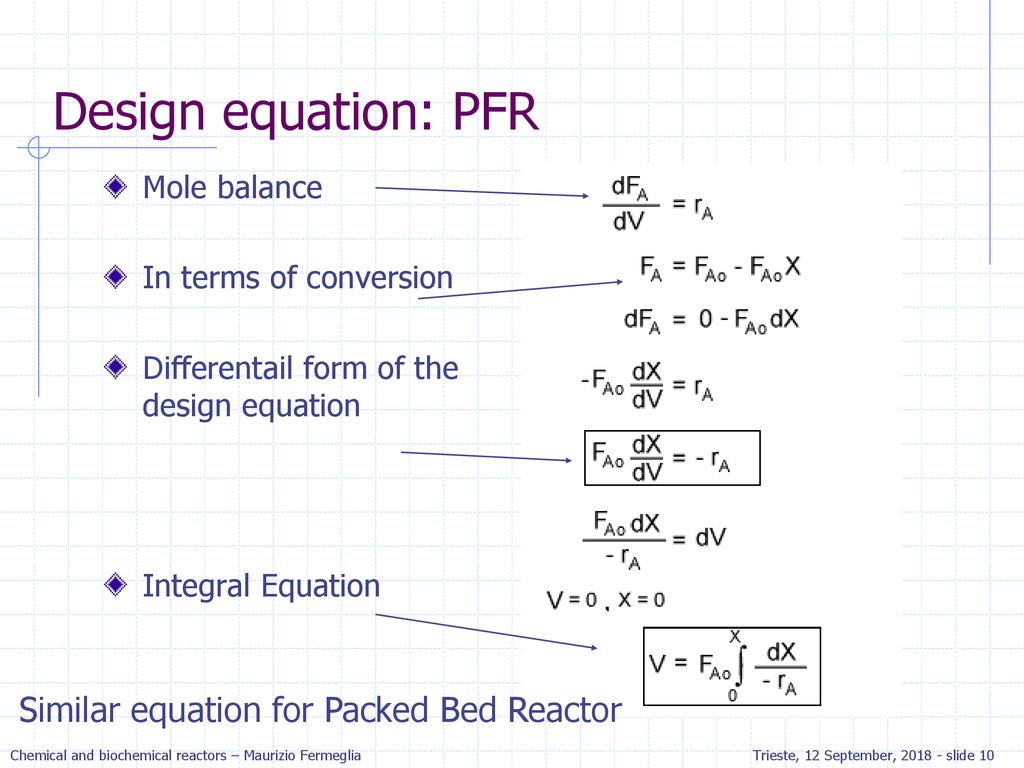

A fluidized bed is a packed bed through which fluid flows at such a high velocity that the bed is loosened and the particle-fluid mixture behaves as though it is a fluid. Three-Phase Reactors 4121121 Trickle -Bed Reactors 4121122 Gas-Fed Slurry Reactors 413113 Moving Solids Reactors 4131131 Bubbling Fluidization 4161132 Fast Fluidization. For batch reactors conversion is a function of time whereas for flow reactors at steady state it is a functionofvolume 222 CSTRDesignEquation Using the expression for the volume of a given.

Ad Packed Bed Reactor Your safety for production and RD. FigureExpanded views of a xed-bed reactor. Thus when a bed of.

They concluded that the packed-bed reactor had a better performance than structured systems due. The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix which in turn is governed by the shape dimensions and the. ρ p ρ f g 1 5 0 μ f V m f 1 ε m f ϕ s 2 D p 2 ε m f 3 1.

Types of Packed Bed Reactors There are four major types of packed bed reactors intended for gas phase reactions. Reactors with a commercial multi-tubular packed-bed reactor for methanol synthesis. Ad Packed Bed Reactor Your safety for production and RD.

13161 E ective Di usivity Catalyst 100110 m powder packed into a tube 0416 156 pelletized Cr 2 O 3 supported on Al 2 O 3 022 25. The catalyst weight and rector volume are related by the catalyst bulk density gdm 3. Pres sure drop correlations for packed beds were set up.

The reaction rate per unit volume and the reaction rate per unit catalyst. Single bed adiabatic reactors radial flow reactors multiple. Video Lecture 33 of 43.

1 Trickle-Bed Reactor downward cocurrent two-phase flow Download our Trickle-bed simulator tbsimulzip and the updated version tbsimul_updatezip to simulate mass transfer pressure. Gas solid non-catalytic reaction 2. Packed bed reactor design calculations Written By lonniemayshack57621 Saturday April 23 2022 Add Comment Edit.

Design equations for Packed bed reactor designby IIT Madras. 7 5 ρ f V m f 2 ϕ s D p ε m f 3. From the PFR module we have.

Applications of Design Equations for Continuous Flow Reactors 33. To reactor length leaving us with the following parameters to be evaluated as a function of reactor length the fluid properties. The engineering design of packed bed based unit operations is very much influenced by the structure of the packing matrix which in turn is governed by the shape.

1 Relationship between pressure drop and flow rate The flow of a fluid either liquid or gas through a static packed bed can be described in a.

Conversion And Reactor Sizing Ppt Download

Catalytic Packed Bed Reactor Youtube

How To Find Volume Of Adiabatic Fixed Bed Reactor

Packed Bed Reactor Design Youtube

Chapter 12 Professional Reference Shelf

Design Equation Of Packed Bed Reactor Chemical Reaction Engineering Lecture 09 Hindi And Urdu Youtube

0 comments

Post a Comment